Some engines earn a reputation that borders on myth, surviving abuse, neglect, and huge mileages that would destroy lesser designs. Mechanics often describe these powerplants as practically unbreakable, yet their longevity comes from clear engineering choices rather than magic.

Designers who create these long-lived motors focus on durability first, then layer performance and efficiency on top. The result is a set of shared traits, from conservative power outputs to overbuilt internals, that explain why certain engines keep running long after the rest of the car has given up.

What “bulletproof” really means in engine talk

Enthusiasts and technicians use the word “bulletproof” as shorthand for engines that shrug off years of hard use. Mechanics describe how older cars often feel tougher because engineers sized components generously and placed less stress on the parts in daily driving. That approach shows up in engines that run cool, tolerate dirty fuel or missed oil changes, and still deliver consistent compression after hundreds of thousands of miles.

Writers who examine why some engines are considered unkillable point to simple layouts, stout blocks, and low specific output as core ingredients. One analysis notes that older designs from Jul highlight how fewer moving parts and modest power targets reduce failure points and keep wear under control, which helps explain why older cars often outlast newer, more complex models when owners neglect maintenance.

Shared DNA of the most indestructible engines

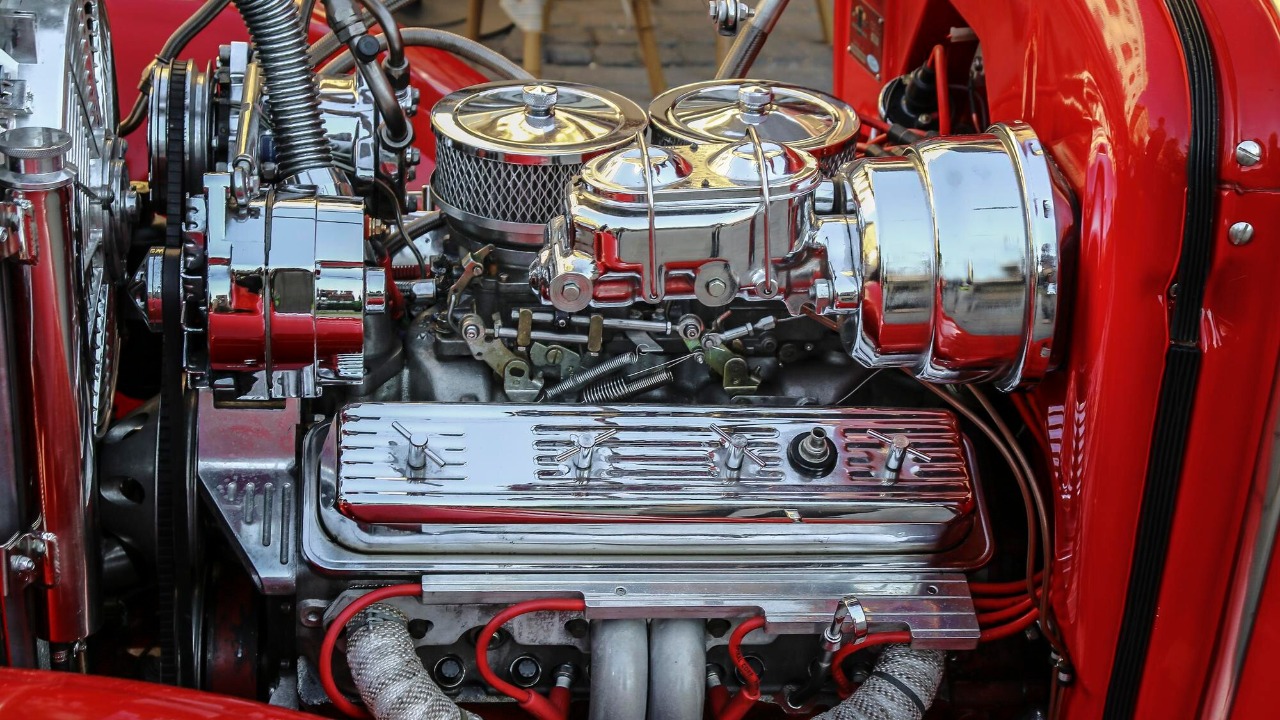

Engines that earn legendary status tend to share a conservative philosophy, even when they power performance cars. Builders keep compression ratios, boost levels, and rev limits within comfortable margins so internal parts never operate at the ragged edge. That restraint lets thick connecting rods, forged crankshafts, and robust bearings handle abuse that would quickly expose weaker designs.

Technical breakdowns of high mileage champions highlight how strength in critical areas matters more than headline horsepower. One deep dive on reliability frames this as Strength in Numbers, where thicker cylinder walls, reinforced main caps, and even carbon fiber components create a safety margin far beyond normal use. That same analysis notes that High performance engines that survive big power often start with this overbuilt foundation, which also benefits longevity at stock output.

Iconic examples that earned their “unkillable” status

Some engines illustrate these principles so clearly that they have become case studies in durability. The Lexus 1UZ-FE V8, for example, arrived when the Lexus LS launched and forced rivals to raise their own quality game. Engineers gave the 1UZ-FE a strong aluminum block with generous bearing surfaces and a dual-overhead cam layout that favored smoothness and low stress, which helped many examples run far beyond typical luxury car lifespans.

Diesel fans often point to the Mercedes-Benz OM 617 as another benchmark for toughness. Reports describe how the Mercedes-Benz OM 617 uses a cast-iron block, simple indirect injection, and low specific output to keep internal loads modest, which lets taxis and workhorses accumulate huge mileages. Video roundups of the most indestructible engines ever built, including one from Sep that surveys several diesel and gasoline legends, reinforce how these designs trade cutting-edge efficiency for a reputation as indestructible workhorses.

Why some brands keep building long-lived motors

Brand reputation plays a powerful role in which engines enthusiasts trust. Owners often cite Honda and Toyota as examples of companies that treat reliability as a core design target rather than a marketing slogan. In one discussion, engineers and fans argue that They invest heavily in validation testing and conservative tuning, which helps explain why Honda and Toyota engines often outlast the bodies wrapped around them.

Owners of older Japanese sedans and coupes frequently share stories of engines that refuse to die even after severe neglect. One thread about the reliability of old Honda engines includes a Comments Section where a user jokes “Not today” after an old motor survives another abuse test, while others credit better cooling and robust bottom ends for that resilience. These anecdotes align with technical claims that careful casting quality, tight machining tolerances, and conservative redlines give such engines a wide margin for error.

Engineering patterns behind reliable and unreliable designs

When engineers compare reliable and fragile engines, they often focus on common design tradeoffs rather than brand badges. One explanation aimed at non-specialists lists a There are A LOT of factors, but it singles out Quality of Materials as crucial. That breakdown notes that Higher grade alloys resist fatigue and heat damage, which lets engines survive detonation events, high temperatures, and long oil change intervals that would quickly damage cheaper components.

Enthusiasts on another forum ask whether reliable engines share a common blueprint, and one commenter argues that halo cars with unique engines and heavy research budgets often show the best durability. That discussion on Nov suggests that overengineering for prestige projects trickles down to mainstream models, which helps explain why some families of engines gain a reputation for lasting forever while others struggle with chronic failures.

How reliability rankings capture real-world toughness

Independent rankings of long-lived engines try to quantify what owners and mechanics already know. Analysts who compile lists of the most reliable car engines look at failure rates, repair costs, and how many examples reach high mileages without major work. One breakdown of What Makes a Car Engine Reliable defines a reliable internal combustion engine as one that withstands thermal stress, mechanical load, and real-world driving conditions while still meeting emissions and efficiency targets.

Those rankings often highlight engines that combine simple architecture with high quality control. They also note that owners still need to follow basic maintenance schedules, because even the toughest design cannot survive without oil or cooling. Lists of the most bulletproof engines ever made, which include the OM 617 and other heavy-duty workhorses, show how these motors conquer roads, fields, and job sites by handling heavy loads and punishing conditions for millions of miles when owners give them even minimal care.

Why modern performance does not always mean fragility

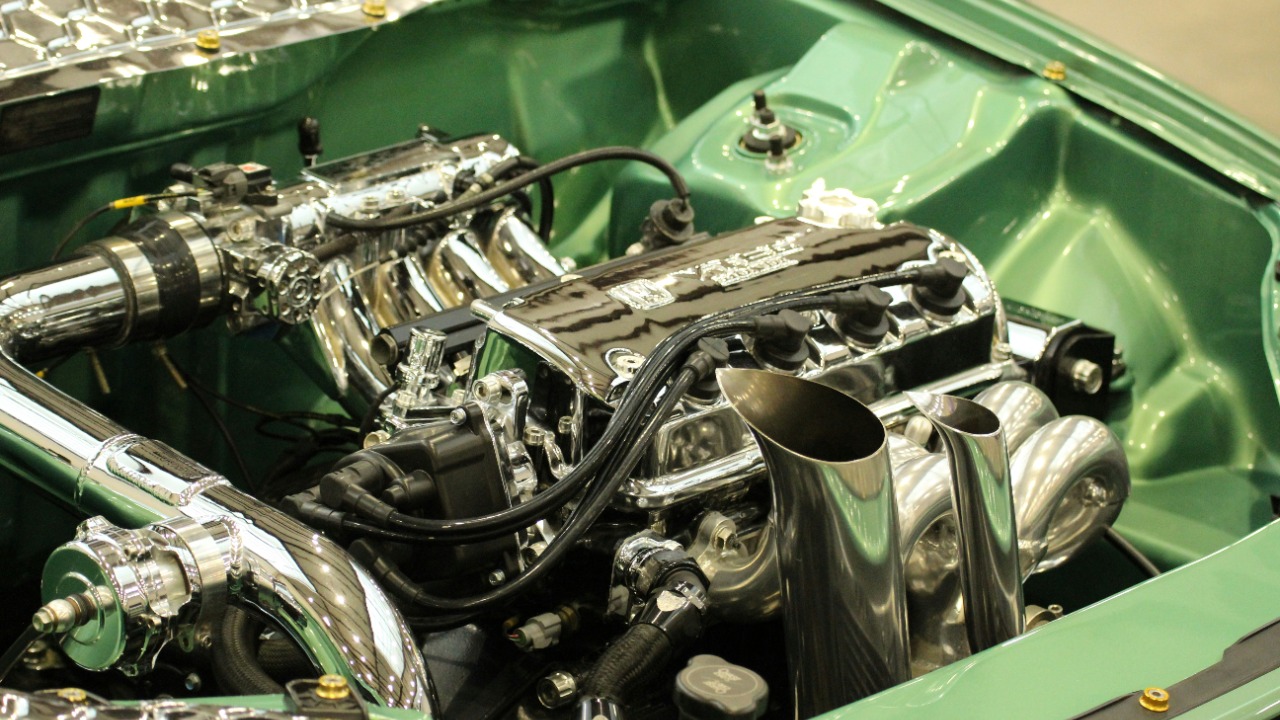

Modern engines often chase power and efficiency, yet some still manage to feel nearly unbreakable. Engineers achieve this by pairing advanced materials with strict testing and conservative tuning in mass production. High output turbocharged engines that last rely on forged internals, strong blocks, and precise engine management that keeps detonation and heat in check.

Technical explainers on performance reliability describe how In the quest for durability, designers use finite element analysis and lab stress tests to identify weak points before engines reach customers. That process mirrors the philosophy behind classic indestructible motors, even if the hardware now includes lightweight alloys and composites instead of only cast iron.

What owners can learn from the toughest engines

Drivers who want a long-lived powertrain can borrow lessons from these legendary designs. Choosing engines with a track record of reliability, modest specific output, and simple layouts reduces the risk of catastrophic failure. Buyers who study reliability guides and owner forums can spot patterns, such as timing chain issues or cooling weaknesses, before they commit to a particular model.

Guides that profile the most reliable engines emphasize that a dependable motor still needs proper care. They stress that a reliable internal combustion engine must handle real-world stress, but it also depends on clean oil, intact cooling systems, and sensible driving habits. When owners combine those habits with engines that share the traits outlined in expert breakdowns from What is a reliable engine to enthusiast lists of The Most indestructible designs, they give their cars the best chance to feel practically unbreakable in everyday use.

Leave a Reply