The Caterpillar 797 isn’t a truck—it’s a monument on wheels. Built for the kind of work most machines couldn’t survive, the 797 is a staple in massive mining operations across the globe. It’s not something you’ll ever see on a highway, and that’s exactly the point. This is what heavy-duty really looks like.

With a 400-ton payload, a 106-liter V20 engine, and tires taller than a person, the 797 doesn’t bother with subtlety. It was engineered to do one job—move mountains—and it does it with industrial precision. Let’s take a closer look at what makes it such a giant in every sense.

A Payload That’ll Stun You

The Caterpillar 797 isn’t just big—it’s built to move massive weight. Its payload rating sits at 400 tons, which means it can haul more in one trip than most trucks move in a week. This beast is designed for open-pit mining, where efficiency means fewer runs and bigger loads.

What makes it impressive is how consistently it handles that kind of weight. The truck’s frame, suspension, and braking systems are engineered to take repeated punishment without flinching. It’s not just about capacity—it’s about durability under extreme pressure.

A $5 Million Price Tag—Before Mods

Buying a 797 isn’t for the faint of wallet. A bare-bones unit starts around $5 million, and that’s before any specialized add-ons. Operators usually customize these trucks with region-specific gear or safety features, pushing the final bill even higher.

The investment makes sense in mining operations where uptime is money. Over time, that payload capacity pays for itself, assuming the truck is used efficiently. Still, $5 million buys you a piece of serious infrastructure—not just a vehicle.

The Size of a Small House

At 23 feet tall and roughly 49 feet long, the 797 dwarfs almost everything around it. You don’t climb into this truck—you ascend it. Even the tires are over 13 feet tall, each one weighing about 11,000 pounds.

That kind of size isn’t just for show. The proportions are necessary to balance the massive loads and maintain stability on uneven terrain. If it looks like a building on wheels, that’s because it practically is.

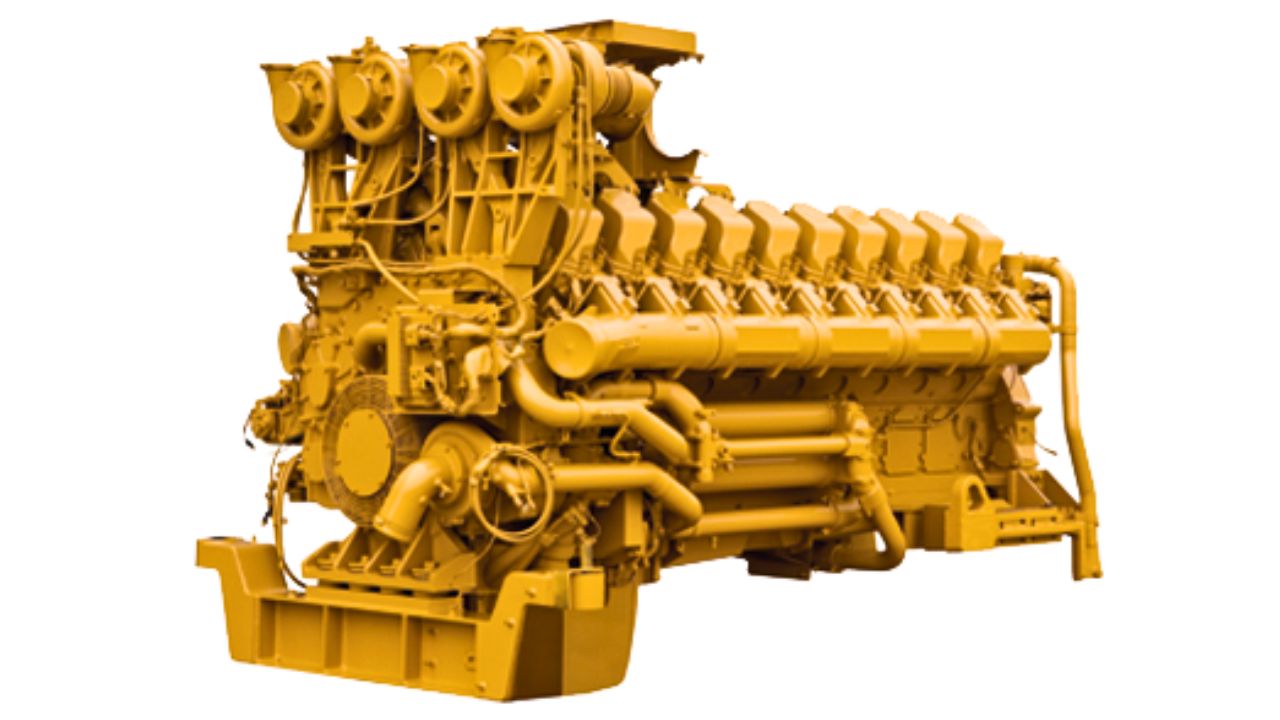

It’s Powered by a 106-Liter Engine

The heart of the 797 is a Cat C175-20, a 106-liter V20 diesel engine that churns out a staggering 4,000 horsepower. It’s one of the largest production truck engines in the world, and it has to be, given what this machine does.

This engine isn’t just about brute force. It’s also built for longevity and low maintenance cycles, designed to run under crushing loads for hours on end without a hiccup. When uptime matters more than finesse, this is the kind of engine you want.

Fuel Tank Big Enough to Swim In

The 797 carries roughly 1,000 gallons of diesel, depending on the setup. That’s not a typo—it’s about four tons of fuel just to keep this machine working. And it’ll need it: the fuel burn rate under load can top 100 gallons per hour.

Fueling up isn’t like stopping at a gas station. It takes industrial fuelers and careful scheduling. Every drop counts when your equipment is this expensive to run—and downtime means lost revenue.

Built for Remote Assembly

You won’t find a 797 rolling off a trailer. These trucks are too large to ship fully assembled. Caterpillar ships them in pieces to remote mine sites, where crews assemble them over several weeks.

That modular design isn’t just practical—it’s essential. In the high-stakes world of mining, every hour of setup is carefully calculated. Even delivery logistics become part of the truck’s performance profile, and Caterpillar designs around that from day one.

4-Meter Tires That Cost as Much as a Car

Each of the six tires on the 797 can cost upwards of $40,000, depending on market availability. Made by companies like Michelin or Bridgestone, these 13-foot-tall tires are engineered to handle the crushing weight and brutal terrain of mining sites.

They’re not easily replaceable either. Mines have to stock them in advance and schedule downtime just for a tire change. In terms of scale and price, you’re looking at rubber that costs more than some SUVs.

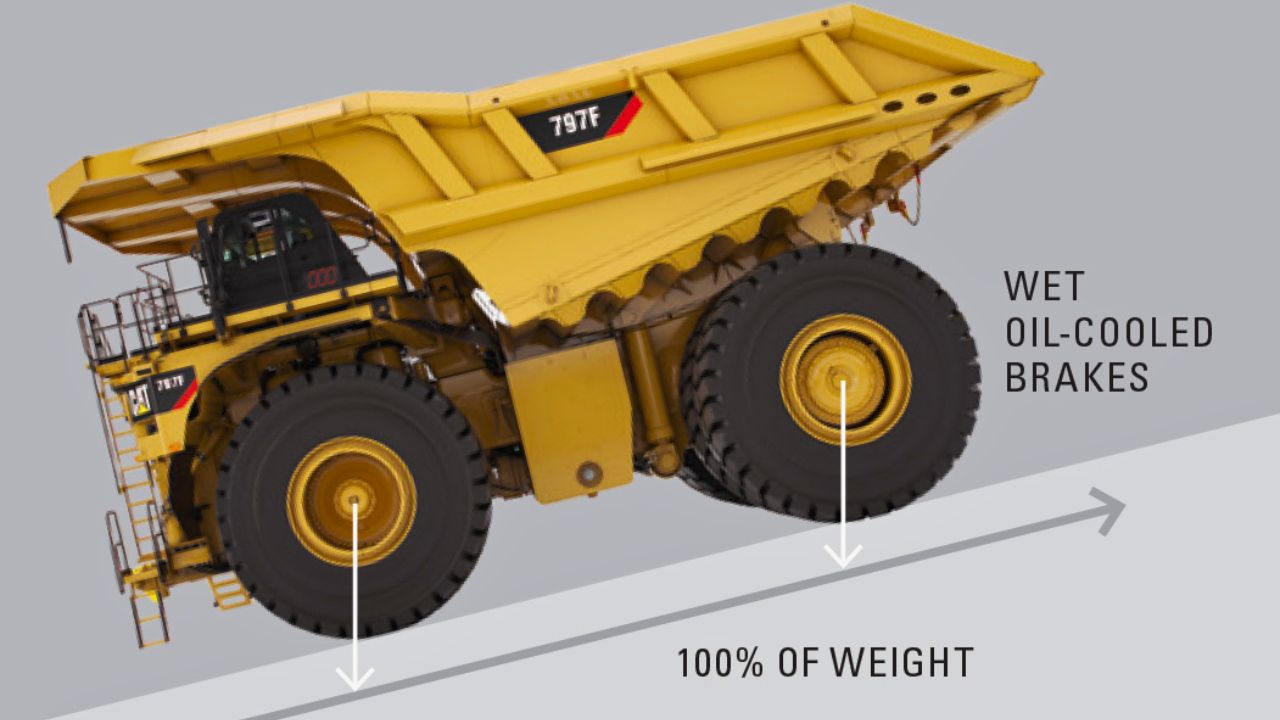

Brakes You Can Trust at 40 MPH

With a full load, the 797 can hit 40 mph. That’s fast when you’re moving 1.3 million pounds. Thankfully, its braking system is more than up to the task, using hydraulically actuated, oil-cooled disc brakes at all six wheels.

It also features an engine retarder and automated control to prevent overheating or fade during steep descents. When you’re barreling down a haul road with hundreds of tons in the back, brakes aren’t optional—they’re mission-critical.

It’s Not Built for Everyone

The 797 isn’t available to the general public. Orders go through Caterpillar’s mining division, and the vetting process is extensive. Mines must show infrastructure, staffing, and long-term need before they’re considered.

Even once purchased, operating one of these trucks requires serious training. Drivers climb multiple stories just to get to the cab, and the onboard systems take weeks to master. It’s less like learning to drive and more like learning to command a vessel.

Proven Performance Since 2009

Introduced in 2009, the 797F replaced the 797B and quickly became a favorite in the mining industry. With thousands now operating worldwide, it has a proven track record for uptime, low cost per ton, and long service life.

Caterpillar has continued to update the 797F over the years, but the core platform remains consistent: massive power, high reliability, and built-for-purpose design. It’s a workhorse built for places most of us will never see—and for jobs most machines could never handle.

Like Fast Lane Only’s content? Be sure to follow us.

Here’s more from us:

Leave a Reply